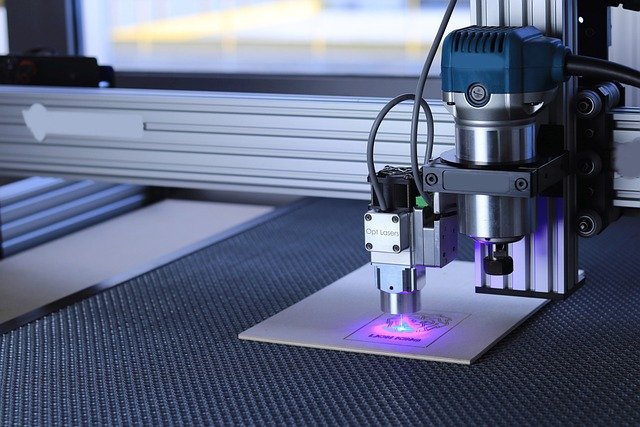

Getting Started with Beginner CNC Machines

Entry-level CNC routers and mills are opening the door to small-shop fabrication, DIY prototyping, and custom engraving—without the steep learning curve of industrial systems. Learn how to evaluate work-area size, motion accuracy, bundled software, and safety features so you can pick a starter machine that matches your projects and budget while leaving room to grow.

What key specs should you compare when choosing an entry-level CNC machine?

When selecting your first CNC machine, several specifications deserve careful consideration. The work area size is crucial, as it determines the maximum dimensions of the projects you can create. For most beginners, a work area of 12” x 12” to 24” x 24” is suitable for a wide range of projects.

Motion accuracy is another critical factor. Look for machines with high-precision stepper motors and robust linear motion systems. A resolution of 0.001 inches or better ensures clean, detailed cuts. Spindle speed is also important, with higher RPMs generally allowing for faster cutting and smoother finishes.

Consider the machine’s frame construction as well. A rigid, stable frame made from materials like cast iron or aluminum helps reduce vibration and improves overall cutting accuracy. Don’t overlook the importance of software compatibility – ensure the machine works with popular CAD/CAM programs to maximize your design options.

How do beginner-friendly controller software and tool-path setups work?

Entry-level CNC machines often come with user-friendly control software designed to flatten the learning curve for newcomers. These programs typically feature intuitive interfaces that guide users through the process of importing designs, setting up tool paths, and controlling the machine.

Many beginner-oriented CNC controllers offer wizards or templates for common operations like pocketing, contouring, and drilling. These features help users quickly set up basic machining operations without deep knowledge of G-code programming. Some software packages also include simulation capabilities, allowing you to visualize the cutting process before running the actual job.

Tool-path generation is a critical aspect of CNC machining. Beginner-friendly software often includes automated tool-path creation based on your imported design. It calculates the most efficient route for the cutting tool, considering factors like material type, cutting depth, and tool diameter. While these automated features are helpful, it’s important to understand the basics of tool-path creation to optimize your projects as you gain experience.

Which safety practices and maintenance steps are vital for a home CNC workshop?

Safety should be your top priority when operating a CNC machine at home. Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and dust masks. Secure loose clothing and tie back long hair to prevent entanglement with moving parts.

Proper dust collection is essential, especially when working with materials like wood or plastic that produce fine particles. Invest in a good dust extraction system to keep your workspace clean and protect your lungs. Regular cleaning of the machine, including removing chips and debris, is crucial for maintaining accuracy and preventing damage.

Implement a routine maintenance schedule for your CNC machine. This should include lubricating moving parts, checking and tightening fasteners, and inspecting belts or lead screws for wear. Keep cutting tools sharp and clean to ensure the best possible results and reduce strain on the machine.

Electrical safety is also critical. Ensure your machine is properly grounded and use a surge protector to safeguard against power fluctuations. Familiarize yourself with the emergency stop function and practice using it before beginning any project.

What are the cost considerations for beginner CNC machines?

When it comes to pricing, entry-level CNC machines can vary significantly based on their capabilities and build quality. Here’s a comparison of some popular beginner-friendly CNC machines:

| Machine Model | Work Area | Key Features | Cost Estimation |

|---|---|---|---|

| Carbide 3D Nomad 3 | 8” x 8” x 3” | Enclosed design, low noise | $2,800 - $3,000 |

| Inventables X-Carve | 29.5” x 29.5” x 4.5” | Large work area, open-source | $1,500 - $2,200 |

| Shapeoko 4 | 33” x 33” x 4” | Rigid frame, high precision | $1,900 - $2,400 |

| Genmitsu PROVerXL 4030 | 15.7” x 11.8” x 2.5” | Compact size, affordable | $400 - $600 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When budgeting for your CNC machine, remember to factor in additional costs such as cutting tools, clamps, and materials for your projects. Software licenses, if not included with the machine, can also add to the overall investment.

As you begin your CNC journey, start with simpler projects to build your skills and confidence. Take advantage of online resources, forums, and local maker spaces to learn from experienced CNC users. With practice and patience, you’ll soon be creating impressive projects and unlocking the full potential of your new CNC machine.